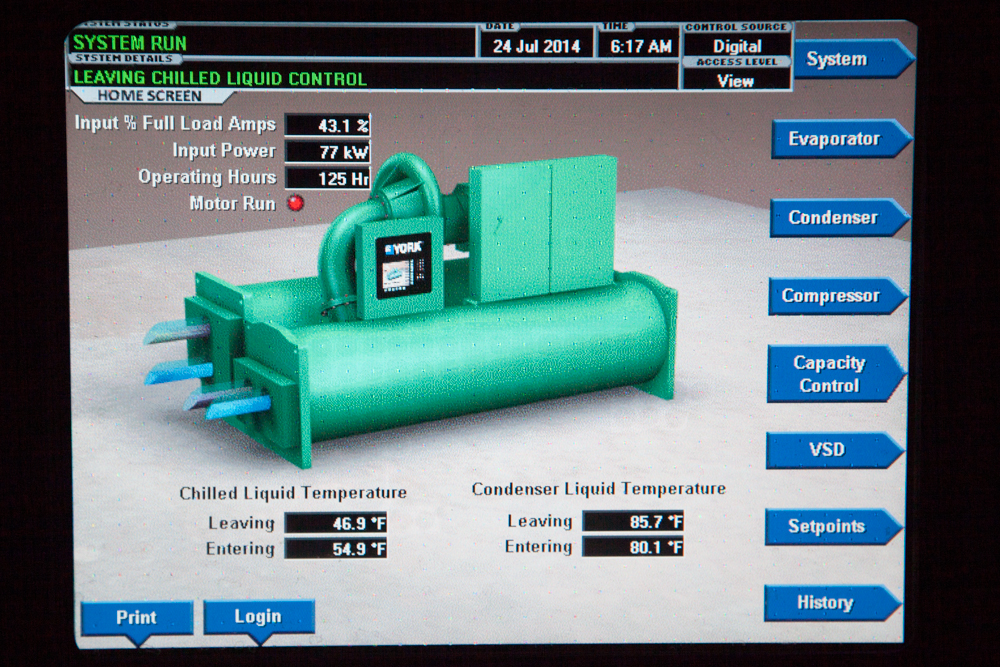

Just over 4 weeks to go – July 24, 2014

This is one of the controllers in the pump room. It means the AC is working, and the temperature inside is nice and cool… at least the second floor.

The doors are in the process of being installed. These doors will open up to the fun areas, the basketball court, and other amenities.

The doors get unlocked, then they slide to the side where they stack. Really slick.

Main lobby area, main staircase.

Just a hallway upstairs right off the cafe area. Finished. Has a very clean look to it.

800 cubicles are going to be on the second floor. They look good. I would say about 30-40% of them are installed. Several crews assembling them.

Dibs!!!!!

The covered parking areas are coming along. Rumor says solar panels will cover the parking areas….

Outside planters are springing up overnight. Lots of concrete and block work going on….

The basketball area arms are in place, and now some huge forms for concrete along the base of each.

Favorite image of the day…. As always all images shot with the Canon 5D Mark II, EF 24-105 F4 IS L lens. Inside shots lit with the Canon Speedlight 580 EX II. All images shot so far can be seen here.

Servers? – July 18, 2014

My guess is that we will have a server room in the new call center, that will have glass walls, so we can see into the room. These are server racks, they are being put into place. The floor contains track for windows. The ceiling is different than anywhere else in the building, (so far). When I toured our server farm, the server racks were positioned to allow cold air for intake on one half of the rows, and the other half to have warm “exhaust” areas, maximizing the cooling of the servers. This area looks like it is laid out the same way. The server farm uses raised floors to help with the cooling. This is an area that the concrete floor was cut and removed for several months. I didn’t pay a lot of attention to what they were adding, but it very well could have been cooling vents?

Rainy Days…? – July 17, 2014

Crane lifting part of one of the “arms” or supports that are going around the concrete slab.

Several of the supports are already in place. They are much bigger in person.

The pop outs are mostly finished at the main entrance, and look really good. Stainless steel, or aluminum?

This area is just inside the main entrance heading north. Getting closer to being finished. Lots of areas have the “drop” ceilings ready for ceiling tiles. AC vents / uptake vents / sprinkler heads are being put into place first.

The main support beams and “crosses” are in place for covered parking and solar? Maybe?

The areas on the edges have massive concrete supports that will hold them upright. The rebar is being welded to the supports. The concrete foundations are as big as a Volkswagen!

The Gym area bathrooms will contain showers and lockers.

Halton. More and more equipment is showing up in the kitchen area. This is an exhaust hood.

This area will be a dish washing area. There is a window that will be open to “return” a tray, plates, glasses, utensils, etc. At least that’s what this area looks like.

Drop ceiling in the serving area. Above the lift on the left hand side, you can see another exhaust hood. For above a freestanding grill, perhaps.

This area is exactly opposite of the kitchen / serving area of the cafe, and it looks like some built in seating? or low plant shelves maybe. This area is getting much closer to being finished out.

GO DADDY G R E E N !!!! Finally some color on the walls! OK so most of the painted areas are white. Its nice to see some familiar GREEN!!!

Second floor, north area, YES its cubicles being assembled. Over 800 on the second floor. I imagine this area will look MUCH different in one weeks time.

Second floor conference room? It will have 2 raised levels of seating. This is exactly above the 1st floor area with the circles above it.

The sinks and fixtures are installed on several of the bathrooms. All touchless, which is as I see it, a nice touch!

The concrete slab with the supports around it, from the roof.

You can see the concrete slab, and some of the concrete bases for more support arms. Just beyond you can see another outdoor feature, with some block work going on. Planters? Outdoor stadium style seating? Perhaps both….. Just a thought.

Some of the crew that is assembling the supports / arms that are going up around the main concrete slab.

Another angle on the biggest outdoor feature, so far. I was surprised when I got to the site and saw these huge supports surrounding the main concrete slab.

All images shot with the Canon 5D Mark II, EF 24-105 F4 L IS lens. Indoor shots got some help with the Canon Speedlight 580 EX II, camera mounted. All of the images taken of the site can be seen at JLPPIX.com, under the “Friends” gallery…. or click here.

Approx 6 weeks left – July 10, 2014

Stormy sky over GoDaddy’s new Tempe Call Center. Camera was sitting on the curbing for the road coming into the facility.

This slab will be for basketball, or tennis, or volleyball???????

South end of the building, sidewalk is being finished.

OK. It looks like the parking will be covered parking, I’m jealous…. Just saying. This would be a good time to put in solar, if Go Daddy is going to put in solar… again …. just saying.

The support beams for the covered parking will be SOLID! That’s a deep hole for concrete.

First floor meeting area? Lots of small rooms off this area for team huddles, or 1 on 1’s. You can see the the ceiling starting to take shape. You can also see the dust in the air. Part of this is from all of the construction, part is because the air handler systems are running. Not cold air, but air movement…. Its a step closer…

Walk in cooler, and walk in freezer.

This area will be for some kind of food storage. The walls and floors are all spill proof, and could be hosed down.

This area in the cafe will most likely be a serving area…. again everything is coming together and you get a real sense of what a tremendous building this is going to be.

A guy making sparks. One of the workers is modifying one of the vents that will connect the hoods above the cooking areas with the exhaust handlers / grease traps on the roof.

Main seating in the cafe … again you can see the dust in the air….

The electricians are tagging everything, once power is live to the individual areas. This is part of the air handling systems, and this area is in the pump room.

Its amazing to see all of the trades working together to get this building finished on time. Miles, and miles of cat 5 cabling is going in for our network.

********** C A R P E T ********** C A R P E T ********** C A R P E T ********** C A R P E T ********** Carpet is going in on the second floor.

This meeting room on the second floor, will have raised seating. Conference room? TV Studio? Not sure…..

********** C A R P E T ********** C A R P E T ********** C A R P E T ********** C A R P E T ********** Carpet is going in on the second floor.

Major walkway on the second floor, looking from north to south. You can see the carpet on both sides….

So……. I’ve figured out if I call “dibs” early enough, I might get my own office. This entire room, (closet) would suite my purposes….so ….. DIBS!!!!!!!

Really neat sky looking east from the roof.

North east parking area, you can see all of the activity. I imagine this area will look completely different by next week.

Main “round-about” when you drive onto the new Go Daddy campus. Lots of dirt work getting ready for foundations, curbing, asphalt, etc. If I didn’t mention it, carpet is going in on the second floor, I understand in the next week or so, the furniture will go in. Some of it is on site now, waiting to get assembled.

All images shot with the Canon 5D Mark II, EF 24-105 F4 IS L lens. Inside shots were helped out with the Canon speedlight 580 EX II. Josh borrowed my 600EX-RT. All of the images shot so far can be seen here.

7 weeks – July 3rd, 2014

Views from several different angles/locations of the asphalt for the north east area of parking. You can see where the planters and lights are going to go in later. The building looks more finished with asphalt.

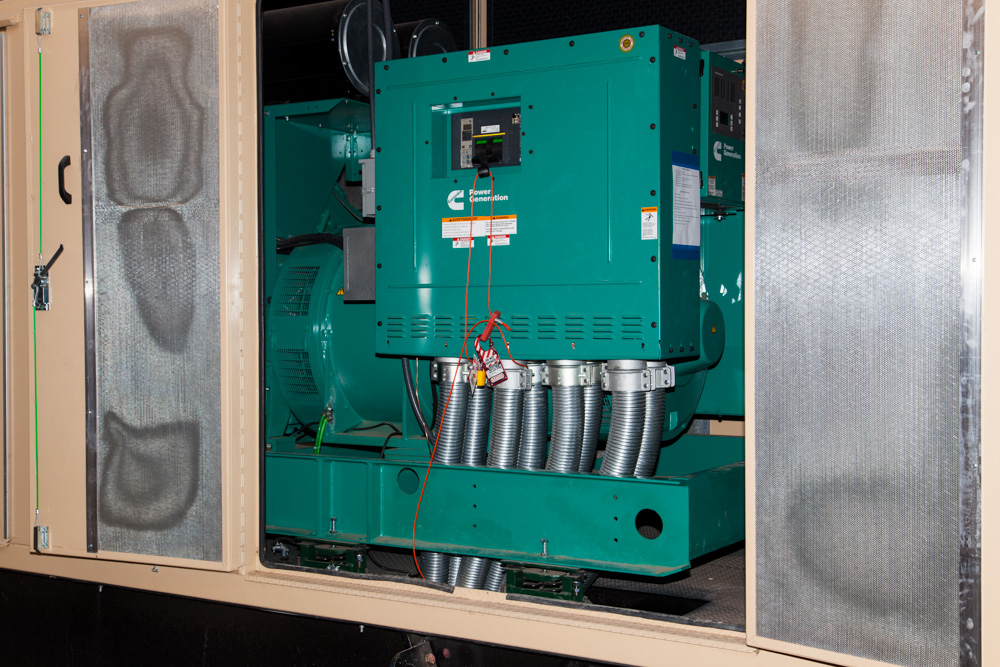

The back up generator is housed in its own building. OK it shares a duplex with the cooling towers. In Gilbert the back up generator is a semi trailer parked out back, as an after thought.

Kitchen and bathroom areas are getting tile for floors, and walls. The spaces are starting to look they are ready for us to go and occupy.

Lighting is going into the 2nd floor north east area.

These “framed” areas will get drywall attached, and hung from the ceiling. The ceiling area has a lot of detail and attention put into it, and you can see in some areas what the finished product will look like.

This is a very special slab of concrete. It was poured to be exactly level, and in such a way as to not crack. Outdoor volley ball, basketball, and tennis courts start out like this……..

All images shot with the Canon 5D Mark II, EF 24-105 F4 IS L lens, and the EF 17-40 F4 L lens. Inside shots getting help from the Canon 600EX-RT flash, camera mounted. All 3900 + images of the progress of our new call center can be seen here.

Baby Doll – July 31, 2013

I had planed on uploading this image for July 1st, thinking that was the half way point of the year. I’ve been posting some videos and working on other projects, so this did not get posted….. yet I’ve been thinking about this image quite a bit lately. I knew I had to get it posted today. Imagine my surprise to find out I took this image exactly 9 years ago today. This image was shot outside of a house that was being torn down. It invokes emotions! Women do not like this picture, especially if they once had a “rag” doll with the stuffed flexible body and plastic limbs and head. Its almost creepy. The sun had deteriorated this one, and it had clearly been abandoned. My wife hates this image. Shot July 31, 2004 5:05 PM on my way home from work. Olympus C750UZ. THis image was shot in “Tiff”. It was an 11.4 megabyte image from a 5.1 megapixel camera. It has survived the years well.

Mark’s new Glock .40 – July 21, 2013

So my brother in law Mark Messner got a new Glock .40. I was able to purchase his old Ruger P95 9mm. This was the first chance we both had to go out and shoot. His Glock feels very solid. Its a “shorty” model with different sized magazines “adding” length to the grip. Comfortable, and seems to be fairly accurate. We both went through 80-100 rounds. Mid 80’s for the temp, but very high humidity. We were the only ones out in the desert shooting. It was a blast. Canon 5D Mark II, EF24-105 F4 IS, at 70mm, f4, ISO-100, 1/200 sec.

Hot, Hot, Hot – July 15, 2013

Lower left hand corner, jalapeno, clockwise yellow wax, habanero, serrano, and the ghost pepper is in the middle.

Seven willing victims.

Randy looking a little worse for the wear.

Raul taking a bite out of the ghost pepper that was marinated in ghost pepper hot sauce.

Above are some images of the PVC Mens Ministry Chile Pepper eating contest. This was held June 22, 2013. We had 7 willing contestants. I had prepared a plate with a jalapeno pepper, which was the mildest pepper coming in at around 5,000 scoville heat units. The second pepper was the yellow wax hot pepper, which comes in at a respactable 10-15,000 scoville rating. Third was the seranno pepper, ranging from 15-23,000 scoville rating. Fourth on the list was my friend the habanero pepper, which ranges from 100-350,000 scoville rating. The fifth pepper was a dried “ghost” pepper (Naga Bhut Jolokia). These peppers were unknown until around 2007. Their scoville rating is over 1,000,000. This was not a timed event. I was impressed with all of the contestants efforts. Randy was the first done at each phase including the “ghost” pepper. I had a bonus ghost pepper that had been soaking in my hottest hot sauce for 30-45 minutes. randy opted out, and had a glass of milk. Big Raulwas a little slower getting there, but he also finished all 5 peppers, and took a bite of the bonus pepper. Raul also seemed calm, relaxed, and did not break a sweat. In watching, I broke out in a sweat, as if I too was partaking. All were good sports.

Below is some information about scoville heat units, and high performance liquid chromatography (HPLC) from Wikipedia.

The Scoville scale is the measurement of the pungency (spicy heat) of chili peppers.

The number of Scoville heat units (SHU) indicates the amount of capsaicin present. Capsaicin is a chemical compound that stimulates chemoreceptor nerve endings in the skin, especially the mucous membranes.

The scale is named after its creator, American pharmacist Wilbur Scoville. His method, devised in 1912, is known as the Scoville Organoleptic Test. In Scoville’s method, a measured amount of alcohol extract of the capsaicin oil of the dried pepper is produced, after which a solution of sugar and water is added incrementally until the “heat” is just barely detectable by a panel of (usually five) tasters; the degree of dilution gives its measure on the Scoville scale. Thus, a sweet pepper or a bell pepper, containing no capsaicin at all, has a Scoville rating of zero, meaning no heat detectable. The hottest chilis, such as habaneros and nagas, have a rating of 200,000 or more, indicating their extract must be diluted over 200,000 times before the capsaicin presence is undetectable. The greatest weakness of the Scoville Organoleptic Test is its imprecision, because it relies on human subjectivity. Tasters taste only one sample per session. Results vary widely, up to 50%, between laboratories.

The modern commonplace method for quantitative analysis uses high-performance liquid chromatography, making it possible to directly measure capsaicinoid content. Spice heat is usually measured by a method that uses high performance liquid chromatography (HPLC). This identifies and measures the concentration of heat-producing chemicals. The measurements are used in a mathematical formula that weighs them according to their relative capacity to produce a sensation of heat. This method yields results, not in Scoville units, but in American Spice Trade Association (ASTA) pungency units. A measurement of one part capsaicin per million corresponds to about 15 Scoville units, and the published method says that ASTA pungency units can be multiplied by 15 and reported as Scoville units. This conversion is approximate, and spice experts Donna R. Tainter and Anthony T. Grenis say that there is consensus that it gives results about 20–40% lower than the actual Scoville method would have given.

Nadia James Celebration – July 14, 2013

Nadia James is cancer free. Let me say that again,…. Nadia James is cancer free. What words could be sweeter to a loving mother and father who have gone through a battle none of us should ever have to endure. Nadia James is cancer free. Eddie, Jeanie, Nadia, and Faith have been forged in the fire and have come out much stronger. It was a blessing to spend a small part of my day with the James family, and close friends to celebrate. Thank you. Additional images will be posted here. Portraits from several years ago are here. All images shot with the Canon 5D Mark II, EF 24-105 F4 L lens.

Happy 4th of July – 2013

OK, Its been a while since I’ve posted. Lots of things going on, just not taking the time to get caught up. Not sure how many hours Jazmin had into making this Fourth of July cake, but it tasted every bit as good as it looked. Every slice was an American flag! Wow, what will she come up with next?? Both images shot with the Canon 5D Mark II, EF 24-105 F4 L lens, ISO-100, 1/160 sec, with the EX 580II camera mounted and bounced off the ceiling.